Introduction

Equipment Composition and Use

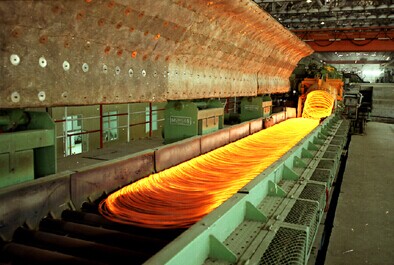

Laying head driving gear box adopts to welding structure. The gear and bearings in the box are thin oil central lubrication process. Spinning head is installed in the safety guard. Center line down to 10 after the water cooling device of finishing mill group and pinch roll. Laying head does the circular motion to change the rolled metal from the pinch roll pushed to the 1080mm diameter spiral coil, and the tile the spiral coil to scattered volume cooling roller bed(downstream equipment), then fall into the scattered volume cooling conveyor.

TAG: laying head gear box finishing mill group pinch roll laying head driving gear box

Parameters

|

Type |

Outlet wire rod

speed(m/s) |

Outlet wire rod

diameter(Φmm) |

Motor power

(DC KW) |

Steel grade |

|

84m/s |

35-80 |

5.5-14 |

75-160 |

Low/medium carbon steel, structural steel, low alloy steel, stainless steel,

valve steel |

|

90m/s |

40-90 |

5.5-16 |

90-200 |

|

|

135m/s |

60-110 |

5.5-18 |

120-220 |

|

|

140m/s |

80-120 |

5.5-20 |

160-220 |

TAG: laying head gear box finishing mill group pinch roll laying head driving gear box

Features

Equipment Main Technical Performance

Type: Horizontal laying head wire rod diameter: Φ5.5~14mm

Coil diameter: Φ1040mm

Maximum spinning speed: 90m/s

Speed increasing ratio: 1.289

Motor type: DC motor Z4-250-41

Motor Power: 110kW

Motor speed: 750/1500 r/min

Lubrication: thin oil central lubrication

Oil pressure: 0.35MPa

Total consumption: 100 r/min

Oils: Mobil 525

Cleanliness: 10μ

Laying head cooling water:

Water pressure:

0.2~0.4 MPa (clean circulating water)

Consumption: 5m3/h

Service:

- We can provide foundation layout and arrangement diagram

- Trustworthy after-sales service, we will send engineers to your factory to install and debug the machines

- Competitive price & excellent quality

- Our machines are easy operation and maintenance

- Lower investment

- Steady performance

- Products are customized for different needs

- Production capability can be adjusted according to customers' request

- Low energy consumption

As a professional laying head for rolling mill machine manufacturer in China, we can supply designing, manufacturing,installation and commissioning of the equipment with "turn-key" service. We can also design, manufacture and revamp other non-standard equipment according to the requirements of users.

Please send us more information about your project, we would like to give you our proposal immediately after getting your details. Sincerely welcome you to come and visit our plant.

TAG: laying head gear box finishing mill group pinch roll laying head driving gear box

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.

Related Products

-

135 Finishing Mill Group

Top cross 45° high-speed wire rod finishing mill designed for the high-speed wire rod production line. Rolling Φ5.5~Φ16...

-

Pinch Roll for Rolling Speed 135m/s

Pinch roll is the horizontal cantilever structure. Pinch roll is arranged before the entrance of wire discharger, respec...

-

10 Stands Top Crossed 45 Degree Wire Rod Mill

10 Stands Top 45 ° high speed wire rod mill, and is located in high-speed wire-rod workshop. Finishing mill unit is comb...

-

Speed Increasing Gear Box of 90m Finishing Mill

Rolling mill speed increasing Gearbox: consist of speed increasing gearbox case, supports base, big gear, transmission a...