Industry News

-

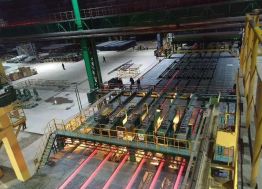

What Is Mini Rolling Mill?

Capacities of mini rolling mill vary in different size. Some big plants may produce as much as 3,000,000 tons per year, the typical size is usually in the range of 200,000 to 400,000 tons per year, but some old or small plants may manufacture as little as 50,000 tons per year of finished product.

MORE -

Advantages and Disadvantages of Direct Rolling without Heating

Direct rolling without heating has the following advantages: It can make full use of thermal energy of continuous casting metallurgy, reduce energy consumption and play the role of energy conservation and emission reduction; reduce the investment of heating furnace equipment, refractory, workshop and production personnel;

MORE -

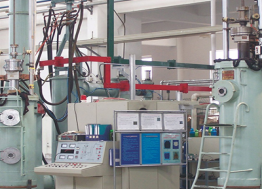

Vacuum Consumable Arc Furnace

The capacity range of vacuum arc furnace is between 15-200 t. The processes of heating, degassing, slag treatment and alloy adjustment are carried out continuously in vacuum. The fully enclosed treatment station combined with the steam jet vacuum pump provides clean smelting equipment without pollution to the surrounding environment.

MORE -

Type of Endless Rolling Technology for Rebar and Wire Rod

Endless rolling has a series of obvious advantages, such as high production efficiency, improving dimensional accuracy by reducing the loss of cutting head and tail to improve the yield, overcoming the dimensional deviation of the head and tail of the rolling piece, reducing the impact of the head and tail of the rolling piece on the motor, transmission system, roll, guide guard and reducing accid...

MORE -

The Development of Rolling Mill

In a broad sense, rolling mill can refer to all equipment used for metal rolling. In the process of metal rolling, there are many equipment with different division of labor. For example, there are main equipment for rolling, auxiliary rolling equipment, and some auxiliary equipment of the rolling mill. What we want to talk about is the rolling mill which mainly carries out rolling.

MORE -

Main Assembly Methods of Rolling Mill

There are more and more structural parts, the rolling mill is receiving more and more attention in assembly. Today I will focus on sharing the knowledge with you, hoping to help you in a way.

MORE -

What Are the Shortcomings of the Hot Rolling Mill?

I have previously talked about the advantages of hot rolling mills, and at the same time, in the actual operation, it also includes some shortcomings. Do you know what its main drawbacks are? For this question, we can answer from four aspects. First, after hot rolling, some non-metallic inclusions contained in the steel are pressed into thin sheets, and delamination occurs.

MORE -

The Advantages of Hot Rolling Mill

The professional rolling mill manufacturer explained that the advantages of hot rolling mill can be summarized into three aspects. First, hot rolling can reduce energy consumption and cost significantly. The second advantage of hot rolling is that it can properly improve the processing performance of metal and alloy materials. The last advantage is that the hot rolling process is more conducive to...

MORE