Industry News

Wire Rod Rolling Mill Rolling Process Analysis

Author : Hani Time : 2022/04/14

Wire Rod Rolling Mill Rolling Process Analysis

According to the rolling speed, there two types of wire rod rolling mills, one is normal rolling mill, the other one is high speed rolling mill, compare with the normal rolling mill, the high speed rolling mill requires higher technology for sure, about the wire rod rolling, there are some matters you have to pay attention to, the wire rod has the following characteristics, small cut surface, very long, requires high accuracy and surface quality, the main rolling process is:

Billet:

The wire rod billets are mainly continues small billet, around 120-150mm, length is 6-12m, during the operation field, visual inspection, Electromagnetic induction detection, ultrasonic flaw detection, etc, those method are often used to detect the quality of billet.

Heating:

Normally use walking beam reheating furnace, the heating with less oxidation and decarburization, the billet would not likely to be twisted, the billet of modern high speed wire rod rolling mill, are big and long, this requires a very even heating temperature.

Rolling:

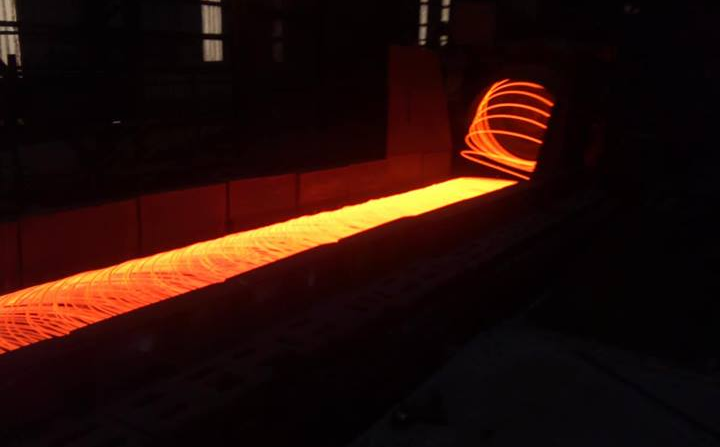

The rolling mill should be very accurate because the cutting surface of wire rod is sole, it’s a very long process and distance from the billet to final product, more rolling mill stands are required, normally needs 21-28 stands, divided in to roughing mill, intermediate mill, finishing mill, high speed wire rod rolling mill can reach speed higher than 100m/s.

Cooling:

The rolling speed right now is very high, which makes the temperature is high and not easy to cool down, to ensure the quality of the final product, loosen coil is normally used for cooling, according to the certain usage of the final product, normally people Pearlite controlled cooling and Martensite controlled cooling.

There is more quality requirement for wire rod, including, surface, accuracy, chemical, mechanical, coil weight, package, and marks.

TAG: Wire Rod Rolling Mil walking beam reheating furnace rolling mill rolling process